- tecido de fibra de vidro revestido de silicone

- rolos de cobertor de soldagem de fibra de vidro

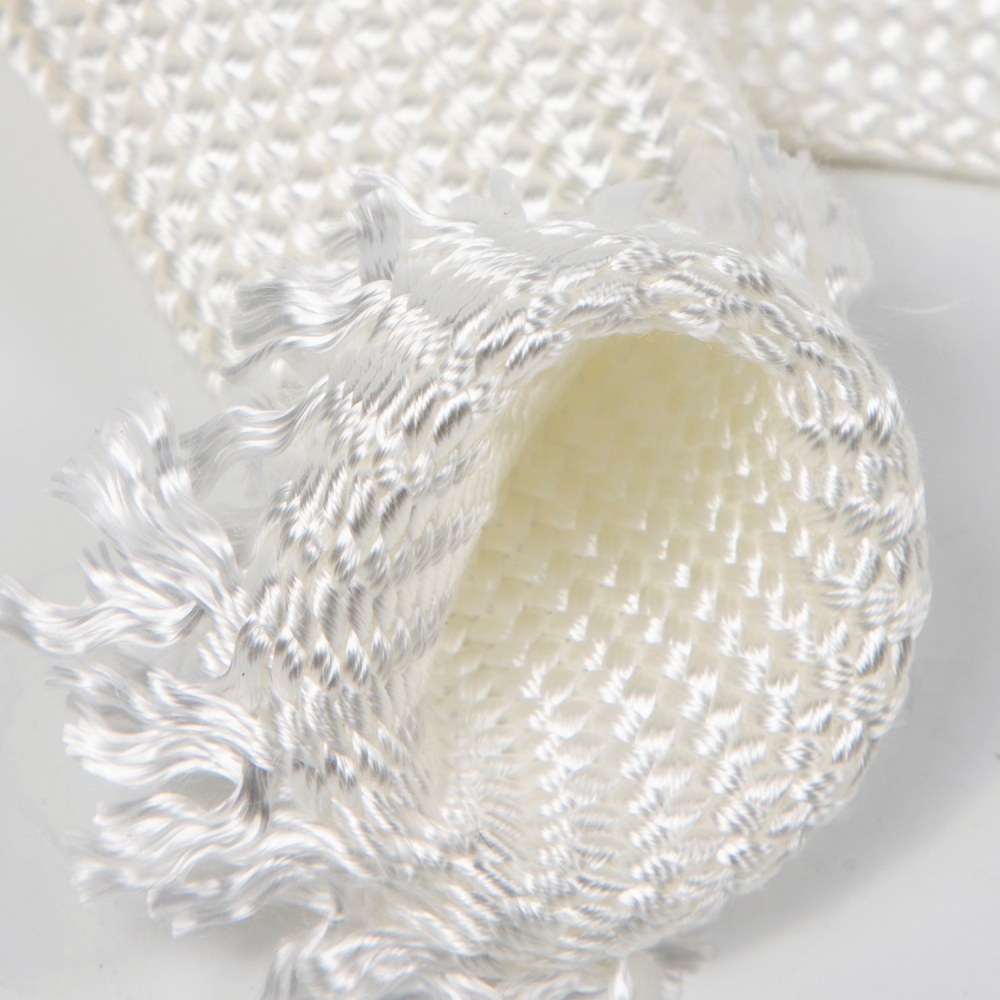

- protetor de mangueira de manga de nylon

- Manga de proteção da mangueira hidráulica

- Manga de proteção de nylon para mangueira

- Mangueira hidráulica manga de fogo protetora

- manga de fogo para mangueira

- manga protetora de mangueira

- Fita de fibra de cerâmica

- tapete de agulha de fibra de vidro com papel alumínio

- NINGGUO BST THERMAL PRODUCTS CO., LTD.

- Envie -nos: vanessa-cheng@live.cn

- Ligue para nós: +86 15856303740

Rede IPv6 suportada

Rede IPv6 suportada